WHAT IS COFFEE PROCESSING?

Coffee processing is the series of steps that occur after coffee cherries are harvested. The main objective is to extract the coffee beans from the cherries and prepare them for roasting. There are different processing methods, but the two most common are the washed (wet) process and the natural (dry) process. In the washed process, the cherries are first sorted and then pulped to remove the outer skin. The beans are then fermented in water to remove the sticky mucilage layer. After fermentation, the beans are washed and dried. In the natural process, the cherries are spread out to dry with the fruit still intact. As they dry, the cherries shrink, and the beans inside develop their flavors. Once dried, the cherries are hulled, and the beans are separated. Each processing method imparts unique characteristics to the coffee beans, affecting their flavor profiles. The washed process often produces coffees with cleaner and brighter flavors, while the natural process can result in sweeter and fruitier notes. Coffee processing is a crucial step in the coffee production chain, as it significantly influences the final taste of the brewed coffee. The choice of processing method depends on factors like regional traditions, desired flavor profiles, and environmental conditions.

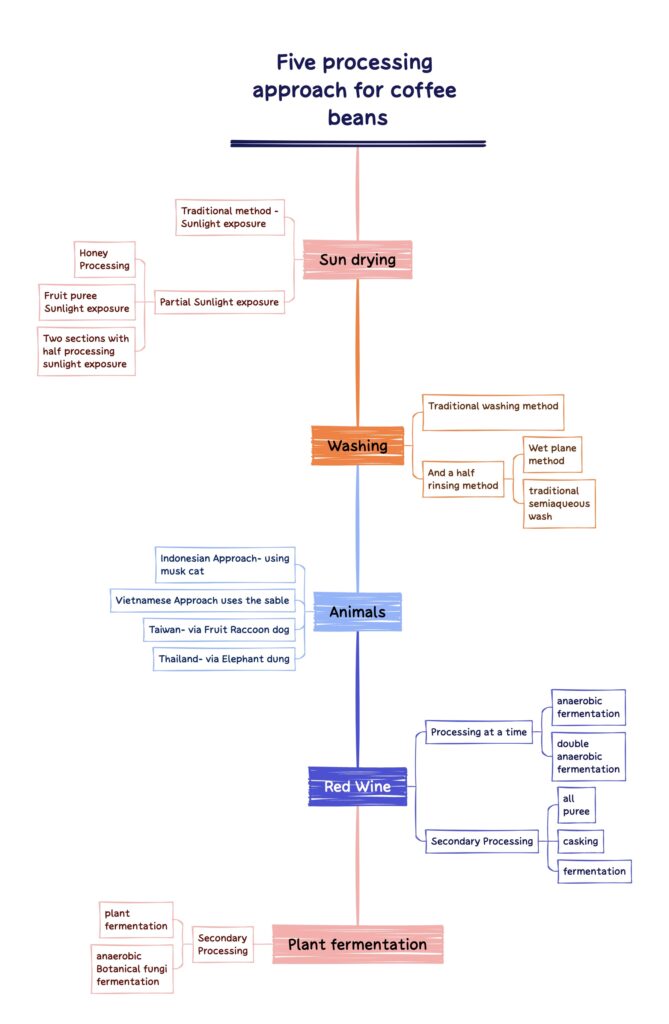

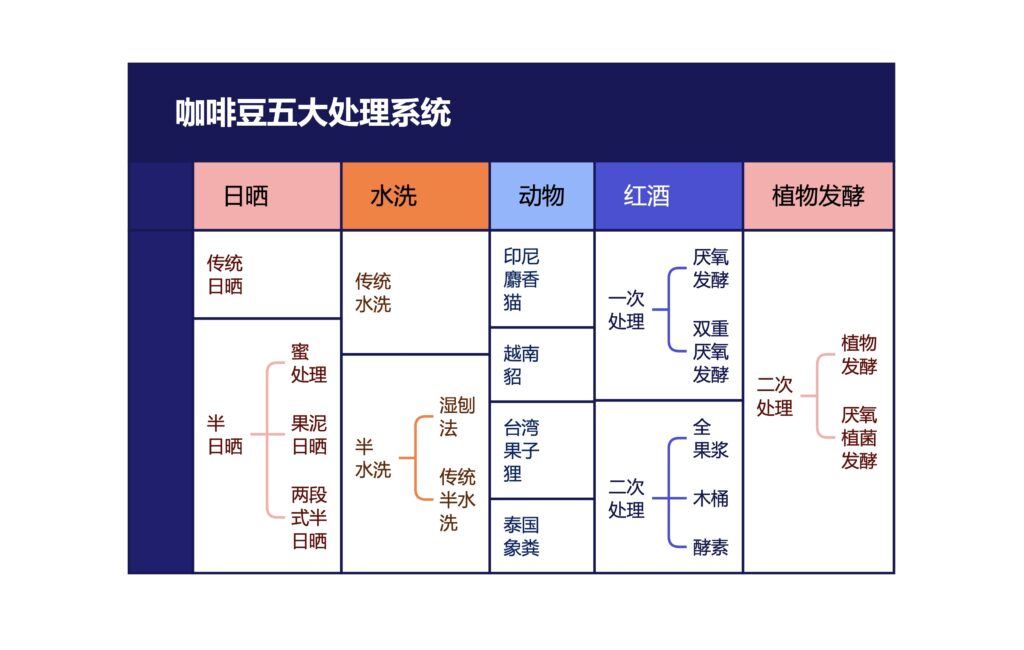

Types of Coffee Processing

The Dry process, also known as the Natural method, is used for processing 70% of Ethiopian coffee beans. It is the oldest and most traditional method of coffee bean processing. Over a thousand years ago, Arabs used this method to process coffee. It involves placing harvested coffee cherries directly on terraces and exposing them to sunlight for about 27-30 days until their moisture content decreases to 11-12%. This processing method is simple and cost-effective, but it comes with various variables and risks. It has been traditionally used for lower-grade beans.

Flavor profile: Soft acidity and balanced bitterness, full body, rich complexity, and pronounced sweetness. High-quality naturally processed beans can exhibit fruity or winey flavors.

In the Dry process, fresh coffee fruits are spread out in exposed areas for sun drying. After continuous turning for about 2 to 4 weeks, the moisture content is reduced to below 12% through natural drying. This ensures even heating of coffee cherries. Once dried, the coffee beans are separated from the husk and skin, and then a hulling machine is used to remove the pulp and parchment. Coffee beans from Ethiopia, Yemen Mocha, Brazil Cerrado, and Sulawesi Island in Indonesia are mostly processed using this method.

The Wet process, also known as the Washed method, is a technique invented by the Dutch in the 18th century. It is suitable for regions with high rainfall. Despite being a labor-intensive process, it is currently the most commonly used method, accounting for about 70% of coffee production. In this process, harvested cherries are separated from the coffee beans using a depulper. The parchment coffee beans are then guided into a clean water tank for fermentation to remove any remaining mucilage layer. The wet processing allows for the selection of immature or defective beans due to buoyancy and better control over the fermentation process. As a result, the flavor profile may not be as intense as in the Dry process, but it exhibits distinct acidity and complexity. The cup presents a solid and clean taste without any astringency or bitterness, although it may lack some richness and complexity due to its “clean” nature.

Wet process steps:

- Floating bean separation: Fresh coffee fruits are rinsed with freshwater, and any floating immature fruits are removed.

- Pulp removal: Fresh fruits are sent to a pulping machine to remove the pulp.

- Mucilage removal: After removing the pulp, the seeds are transferred to fermentation tanks, where they undergo natural fermentation for about 16 to 36 hours to dissolve the surface mucilage. They are then washed.

- Drying and husking: The beans are further exposed for 1 to 3 weeks to reduce the moisture content to 12% before using a hulling machine to remove the husk.

- Wet processing station: Workers receive the fruits and pour them into a receiving tank for pre-soaking. Lighter, unripe beans are removed, and mature fruits are directed to a pulper.

- Fermentation: The pulped beans enter different fermentation tanks based on density and undergo submerged fermentation for 48-72 hours.

- Washing: After fermentation, the beans are transferred to another tank, filled with clean water, and allowed to sit for 4-8 hours. They are repeatedly washed in a washing channel, where the main flavors develop.

- Drying: The washed beans are lifted from the water, with the mucilage layer completely removed. They are drained and transferred to drying racks for sun drying.

Compared to other countries’ wet processes: The fermentation method used in Ethiopia involves submerged fermentation, where the water in the fermentation tanks covers the parchment beans. This differs from the prevalent dry or anaerobic fermentation used in Central America. After fermentation, the wet processing stations in Ethiopia move the parchment beans to another tank and soak them in clean water for 4-8 hours before guiding the beans through a washing channel with flowing water, where workers use wooden paddles to guide them and eliminate poorly dense beans. This differs from the Kenyan-style double soaking method. After a period of settling and drying, the beans are moved to drying racks until the moisture content reaches 11.5%, after which they are bagged and stored in a cool warehouse for further maturation.

Honey Processing, also known as the Honey Method or Miel Process, refers to the sticky mucilage layer that remains on the coffee beans before sun drying, giving a honey-like sensation. When the coffee pulp is separated from the beans, the surrounding mucilage layer undergoes sun exposure and absorbs moisture from the air, causing it to become sticky. Here, “honey” refers to the sticky mucilage layer of the coffee fruit. After harvesting, the fruit is processed using a depulper to remove the outer skin, while leaving the pulp intact. The pulp is then sun-dried, allowing the sweetness of the pulp to penetrate the beans without the need for as much time as the traditional sun-drying method.

The Anaerobic processing method, also known as the Carbonic Maceration method, is a relatively new and innovative approach to coffee processing. It involves fermenting coffee cherries in a completely oxygen-free or low-oxygen environment. This lack of oxygen creates a unique fermentation process that can result in distinct flavors and aromas.

In the Anaerobic process, ripe coffee cherries are carefully selected and placed in sealed containers or tanks with controlled temperature and pressure. The cherries undergo fermentation inside these anaerobic conditions, allowing the natural sugars and acids in the cherries to interact with the coffee beans.

The fermentation time can vary, ranging from a few hours to several days, depending on the desired flavor profile. After fermentation, the coffee cherries are typically washed and then dried, either by sun drying or using mechanical dryers.

The Anaerobic processing method is known for producing coffees with complex and unique flavor profiles. The lack of oxygen during fermentation can result in flavors that are fruity, wine-like, and even reminiscent of fermented beverages. The process can also enhance sweetness, acidity, and body in the cup.

It’s worth noting that the Anaerobic process requires careful monitoring and control of fermentation conditions to ensure consistency and avoid potential defects. This method is often used by specialty coffee producers who aim to experiment and showcase the potential range of flavors that can be achieved through different processing techniques.